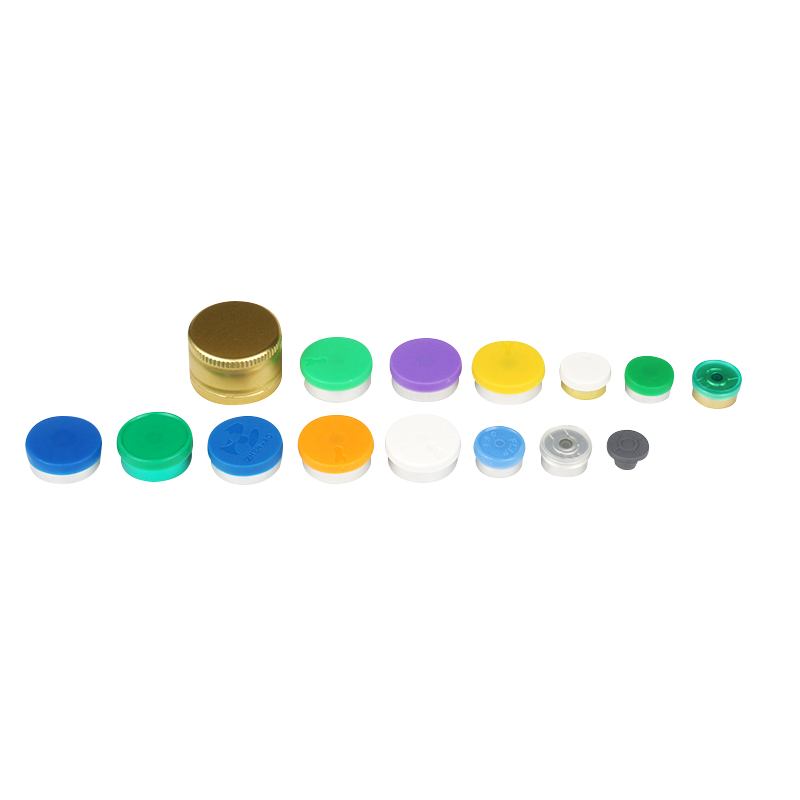

Flip off & Tear off Seals

Flip-Off Caps: With easy finger pressure, users can flip the lid up and expose the container opening, making it convenient to access the internal liquid or medication. This design not only provides effective sealing, prevents external pollution, but also ensures the usability of the container. Flip Off Caps are typically made of materials such as aluminum or plastic, with customizable color and printing options.

Tear-Off Caps: This type of cover has a pre cut section, and users only need to gently pull or tear this area to open the cover, making it easy to access the product. This design is more convenient in some situations, especially in applications that require quick opening and ensuring sealing. Tear caps are usually made of aluminum or plastic, providing reliable sealing performance while also adapting to different packaging specifications and shapes. They are commonly used in fields such as injectable drugs and oral liquids to ensure that the product remains closed and hygienic before use.

1. Material: Aluminum or plastic.

2. Shape: The shape of the flip cover head is usually circular, matching the diameter of the container to ensure good sealing. The top of the cover is equipped with a metal plate that can be easily flipped, and users can easily open or close it by pressing it with their fingers. The shape of the tear cap is usually circular, but in design it usually includes a pre cut section, making it easy for users to tear it when in use.

3. Size: Suitable for various container calibers and sizes, which vary according to different container calibers and packaging requirements.

4. Packaging: packaged separately or together with a container to ensure that the product remains intact during transportation and storage.

The production of flip cover heads usually uses high-quality aluminum or plastic materials. These materials not only ensure the strength and durability of the cover, but also comply with the relevant hygiene standards for drugs and medical supplies. The production of tear caps also uses high-quality aluminum or plastic materials. This ensures the strength and durability of the product, making it suitable for sealed liquid drugs and oral liquids.

The process of manufacturing flip cover heads and tear cover heads includes multiple steps such as mold manufacturing, raw material mixing, molding, coating, and installation of flip cover mechanisms. The precision of the production process is crucial to ensure the consistency and quality of the flip cover head. Strict quality inspection of the cover head is essential in the production process. The steps of size measurement, sealing test, and appearance inspection ensure that the product meets industry standards and provides reliable sealing.

Flip caps are widely used in the pharmaceutical and medical industries to seal drug bottle openings. Its convenient flip design makes it very convenient to use in various scenarios such as laboratories, hospitals, and homes. Tear caps are commonly used in applications that require quick opening and maintaining sealing, such as liquid drugs, oral liquids, etc. Its tear design makes it very convenient to use.

When packaging products, attention should be paid to protection and hygiene. They can be packaged separately or together with drug bottles to ensure that they are not contaminated or damaged by external factors during transportation and storage. Providing post purchase support is an important part. After sales service may include instructions for use, product maintenance recommendations, and quick response to customer inquiries to ensure that customers have a satisfactory user experience with the product.

Payment settlement usually follows the methods stipulated in the contract, which may involve prepayment, payment after delivery, and other methods. Collecting customer feedback is the key to continuous improvement. By understanding customer satisfaction, identify the strengths and weaknesses of the product in order to make adjustments and improvements.